Power inflatable cabinets are subject to dry leak detection. The workpiece and the vacuum chamber shall be vacuumized simultaneously, so that the pressure difference inside and outside the workpiece is not more than 0.05Mpa; helium will be filled into the inspected workpiece; the vacuum chamber method shall be applied to the gas tightness testing of the helium mass spectrometer, with which the inspected workpiece will be determined to be qualified or unqualified. Then the helium inside the inspected workpiece will be recovered and recycled, and finally the workpiece is filled with SF6 working gas at the specified pressure.

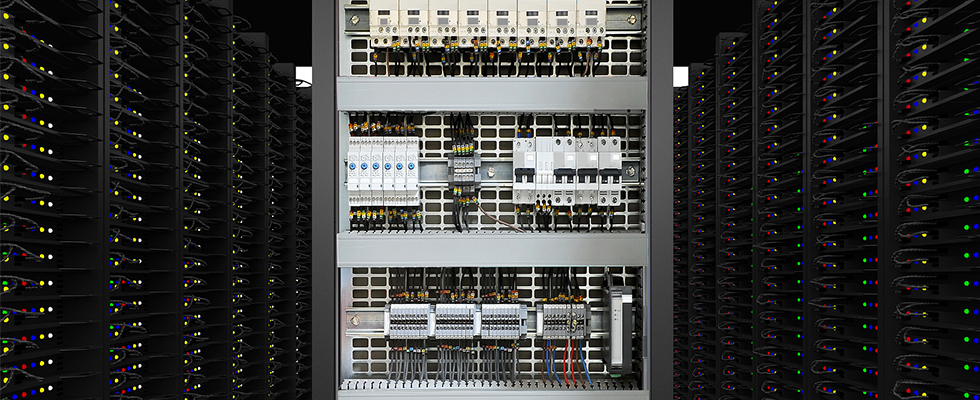

Helium-filled recovery section, vacuum chamber leak detection section, leak detector section, SF6 filling section and electrical control system.

1. The size of vacuum chamber can be customized according to the size of workpiece; the equipment size and layout can be customized according to the workshop;

2. It is equipped with a left-right sliding door and a platform outside the chamber, so that workpieces can get in and out of the chamber smoothly and conveniently;

3. There are several independent joints reserved in the chamber, so multiple workpieces can be detected at the same time;

4. The helium can be recycled, with a recovery rate as high as 96%, which can reduce the use-cost;

5. High-end configuration, standardized design and production, and stable and reliable performance;

6. The system has automatic helium cleaning function, which can quickly and efficiently clean the helium pollution caused by leaking workpieces;

7. The automatic in-and-out chamber function (optional) can be selected to connect the automatic line and realize full automatic detection;

8. The functions of vacuum dehumidification and hot nitrogen dehumidification (optional) can be selected to reduce the micro-water content in the workpiece;

9. The online micro-water detection function (optional) can detect the micro-water content of helium source in real time;

10. The system integrates industrial IoT technology, and the detection process can realize intelligent production such as real-time storage, monitoring and diagnosis;

11. Customized upper computer software development services can be provided according to customers' manufacturing and production MES needs.

Xiamen Huatech

Beijing Sojo

Shenzhen Yiliu

Related product recommendation